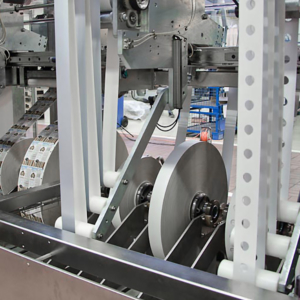

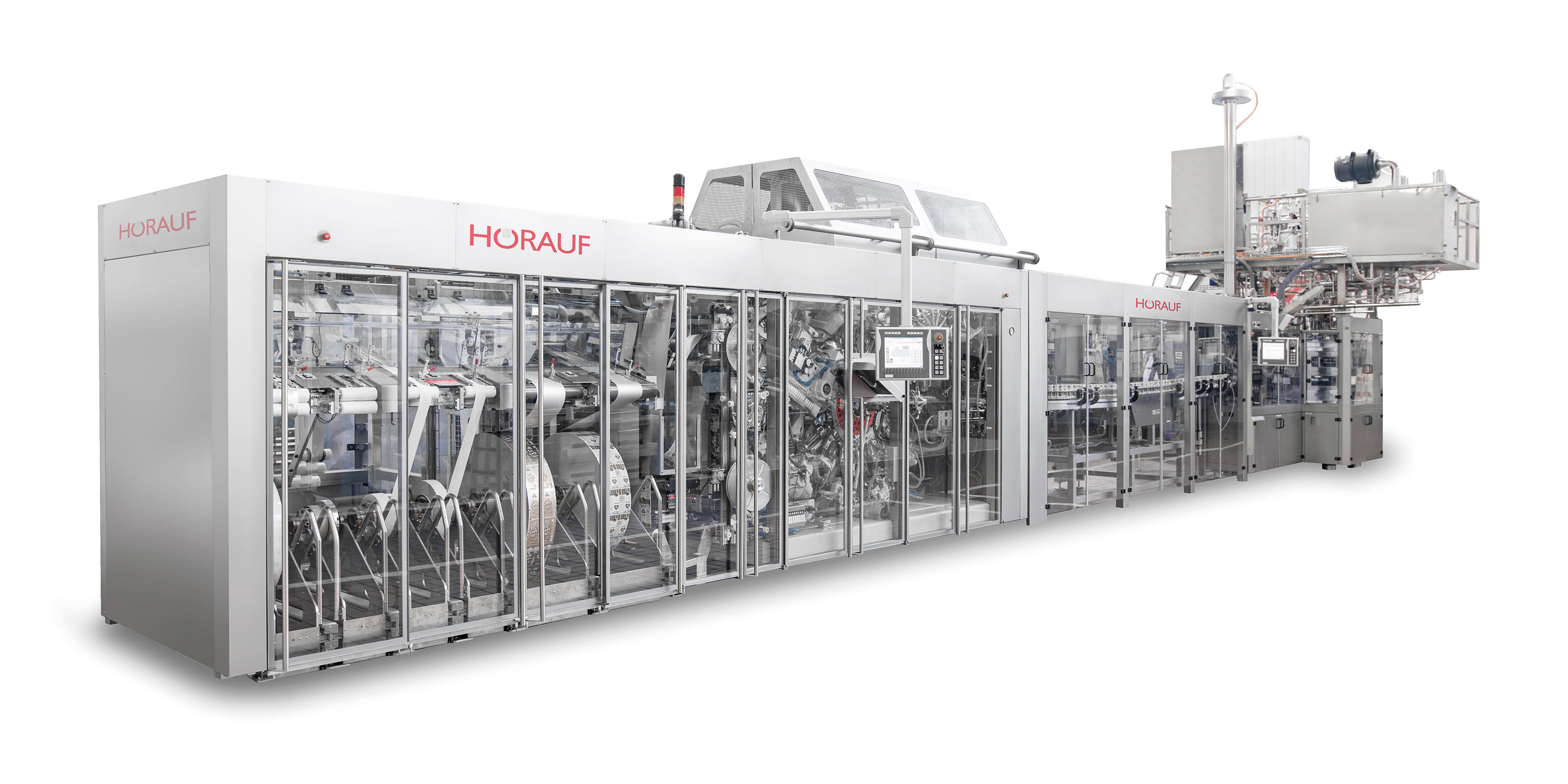

Reel stand Top / Bottom

Reel stand Body

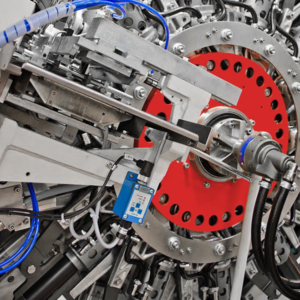

Can forming unit

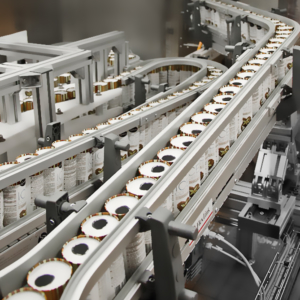

Transport and Buffer

Pull-tab application

Aseptic filling

CartoCan® – modern, flexible, environmentally friendly

CartoCan® is primarily aimed at branded companies looking for a flexible, modern and environmentally friendly system to package their product. The manufacturer becomes the packaging producer and you will have us for a partner throughout the process. This starts with the design of the packaging, where we will provide you with suggestions and samples, and continues with the consultation and preparation of prototypes, right up to the fully installed and production-ready system – and of course afterwards as well. Service, spare parts, extensions, design changes and more – we are there for you and support you in all requirements.

CartoCan®– convincing advantages

Producing the packaging in-house offers you various advantages. First and foremost, you can dispense with expensive storage of prefabricated packaging. Instead, you produce your packaging just-in-time directly from the roll. Product change? No problem. Simply change the material roll and produce the packaging for a new product. New product launch or relaunch: CartoCan® is particularly useful for a new product launch or relaunch.

The system offers a wide range of possibilities in terms of shape, finishing and the function of the packaging.

Hörauf – There is no substitute for experience

Since the 1960s, Hörauf has been manufacturing machines for the food service industry, and has accumulated broad experience in processing paper composites and forming them into containers that meets the highest requirements of form and function. To those who understand it, this is truly an art. With our experience as manufacturers and working with diverse paperboard structures, we are pleased to be your partner-of-choice to realize the diverse packages you have envisioned.